|

Penglai Shuicheng cast basalt pipe and valve Co., Ltd.

|

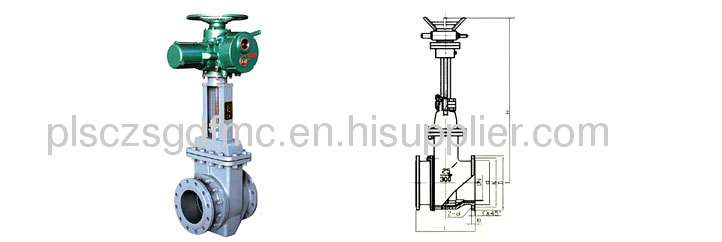

wear-resistant gate valve

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

it includes the ash gate valve,wear-resisting gate valve,ball valve,throttle valve, and slag off check valve.

Wear-resistant valve is a product which is studied as a ash thermal power system resisting abrasion and short-life.Front and back flow,meeting-flow-surface and flashboard use alloy steel,cast basalt,structure ceramic as main materials.Feasures include hoist flexible,sealing performance,self-cleaning function of the gate slot fouling and long life so that it is more than ten times than general valve.With this festure,it is choosed by thermal power plants,mining as wear-resistant pipeline.

Implementing agencies are three forms of electric,pneumatic,manual,and it also can be designed by different requirements of different clients using in various manners of implementation,connection of struction and implementation of structural link.

Description:

Applications and Specifications:

The newly developed product features reasonable structure, flexible opening, long life, etc., mainly applicable to iron ores and molybdenum ores under nominal pressure less than 6.4MPa and temperature ≤ 100 ℃, ash pumping conveying pulp ash, slag-water mixture systems, used as new on-off wear-resistant scum gate valve.

Description:

Applications and Specifications:

The newly developed product features reasonable structure, flexible opening, long life, etc., mainly applicable to iron ores and molybdenum ores under nominal pressure less than 6.4MPa and temperature ≤ 100 ℃, ash pumping conveying pulp ash, slag-water mixture systems, used as new on-off wear-resistant scum gate valve.

Main Parts Material:

Part Name | Material | ||||

10C | 16C | 25 | 40 | 64 | |

Valve Body | WCB(ZG230-450) Stainless Steel | ||||

Valve Cover | WCB(ZG230-450) Stainless Steel | ||||

Valve Seat | NMS1 alloy | ||||

Valve Plate | NMS1 alloy +WCB(ZG230-450) | ||||

Valve Stem | 2Crl3 or 1Crl8Ni9Ti | ||||

Valve-stem Nut | Casting Aluminum Bronze ZCuA19Mn2 | ||||

Hand Wheel | QT400-17 | ||||

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Wear Resistant Ceramics

Wear Resistant Steel Plates

Wear Resistant Pipe

Wear-Resistant Ceramic

Gate Valve

Brass Gate Valve

More>>